Address

6085 Court Street Road, Suite C

Syracuse, NY 13206

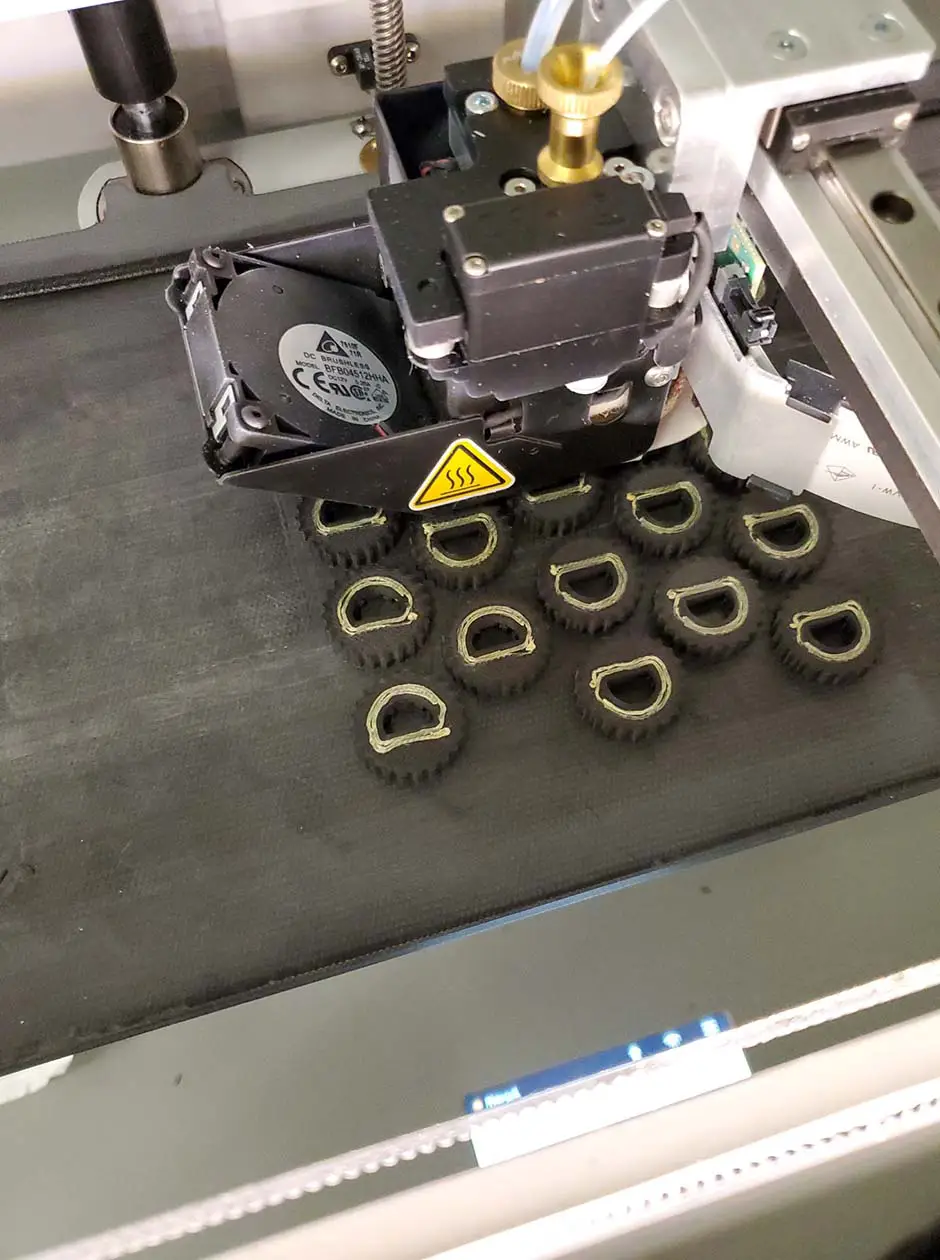

Materials & Process

Importance of Materials & Process

Vetted Tech Inc. is the source for VETTED METAL™. We take great pride

in our AS9100D

quality system registration and our continuous efforts to assure consistent production

of

high-performance metal parts. Our raw materials are DFARS compliant, and we take the

steps necessary to

assure that our 316L and 17-4 stainless steel metal powders are properly stored,

handled, sieved, and

tested to assure that our builds are of the highest quality and consistency.

The same holds true for our Markforged Copper, Tool Steels, and Inconel 625 metals. We

source directly

from Markforged and assure that our materials are stored and employed in accordance with

the

manufacturer’s instructions. We hold our Markforged Onyx, PLA, TPU95A, and Nylon

materials to the same

high standards and take even greater precautions with our Aramid Fiber and Continuous

Carbon Fiber

reinforcement materials.

Rigorous machine capability verification on our EOS M290s and Markforged machines

assures that your

parts meet the high standards we set for our VETTED METAL™ materials

and processes. Our

quality system requires that we calibrate our inspection equipment on a frequent basis

so that we assure

the accuracy of the parts we produce whether it is our basic calipers and micrometers or

our advanced

CMM machine.

If you have any questions about our materials, you can find information at the links

below or just reach

out to us for a personal consultation. Our mission is your success.